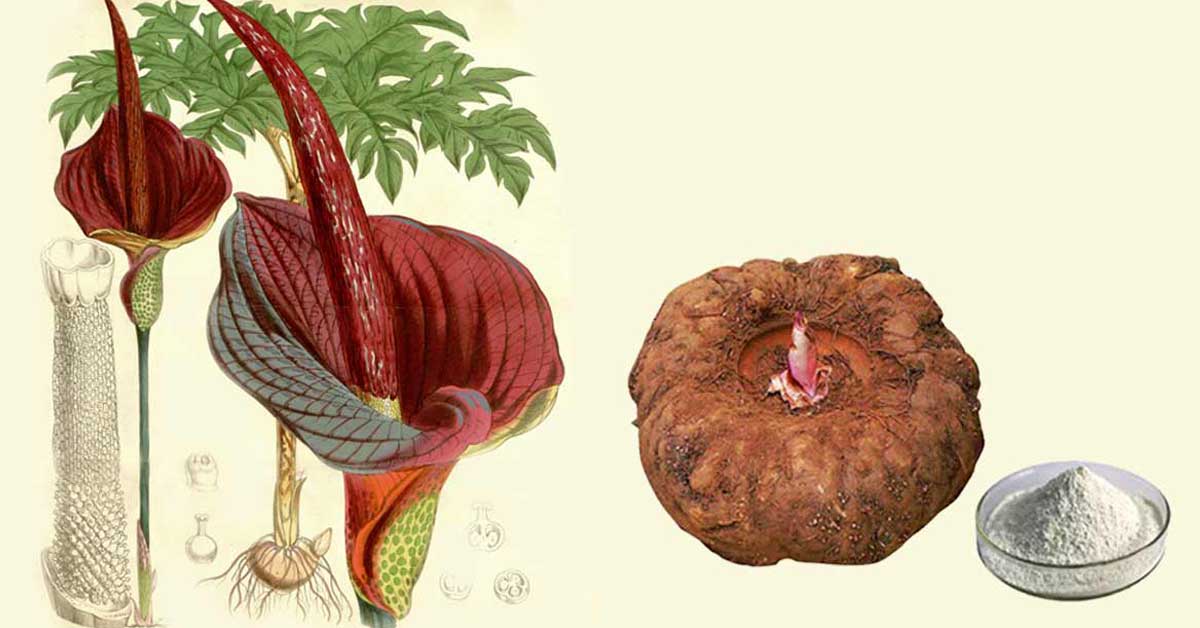

1. Konjac flour definition

1, Konjac flour to konjac bulb as the raw material made of powder, is a non-categorized, grade of the general term.

2, Konjac whole powder (Japan called coarse powder) konjac bulb whole component of powder.

3, Konjac fine powder and fly powder.

Konjac whole powder is separated from the crude glucomannan particles known as konjac fine powder, the rest of the components (mainly starch) constitute the powder known as fly powder.

Because its specific gravity is smaller than the glucomannan, dry production, after the wind separation, starch and impurities such as fly when it is collected to become fly powder, fly powder as a by-product.

2. The principle of Konjac flour processing

Konjac bulbs of ordinary thin-walled cells containing starch, often called starch cells, heterocysts containing glucan, and complete translucent particles, often called glucan particles or fine powder particles.

The characteristics of these two types of cells differ greatly, starch cells are small, brittle, easily broken into dust, starch particles only 0.004mm in diameter, insoluble in cold water, drops of I2-KI liquid in the konjac bulb slices, starch cells show blue.

Heterocells contain complete glucomannan particles, a diameter of 0.15mm ~ 0.45mm, the toughness and hardness of the cell are very great, and not easy to break.

The glucomannan contained in water, hetero-cells around the tightly wrapped ordinary cells and their cellulose, etc., like a fishnet, it is difficult to get rid of the net.

Konjac flour contains starch, glucan, and other impurities. The purpose of fine powder processing is to separate glucan from starch and other impurities, the more complete the separation and purification, the higher the quality of fine powder, Konjac flour processing has two categories of dry and wet methods, and the principle of its addition is as follows.

2.1 Principle of dry Konjac flour processing

Due to the toughness and hardness of ordinary cells being smaller than the iso-cells, the use of mechanical crushing methods, so that the ordinary cells are first broken, in which the starch, cellulose, and other impurities are gradually crushed into fine particles of fly powder.

Glucan iso-cells are extremely strong toughness, in the general conditions of crushing will not be broken. The size and weight of particles are more than the impurities such as starch, as long as the sieve or the wind separation method can be starch impurities such as The impurities such as starch can be removed by sieving or wind separation.

But glucan particles wrapped around the ordinary cells and impurities like fishnet must continue to collide in the machinery, friction, rubbing, and particles between each other collision and friction may be gradually detached. The machinery of the wind will gradually remove these impurities to get the translucent konjac powder particles.

2.2 Konjac flour wet processing principle

Wet processing is also based on the differences between the heterogeneous cells and ordinary cells in toughness, hardness, particle size, etc., for crushing, grinding, and separation, the difference is that the wet method uses a liquid medium.

Water is generally the cheapest liquid processing medium, but because dextran is very easy to dissolve and agglomerate in contact with water, it is not possible to use water as a processing medium. Therefore, the medium needed should be a liquid medium that can inhibit the swelling of glucan, but not change the nature of glucan, called “solvent-blocking”.

In the presence of a resisting solvent or contact with water for a very short period, glucan hetero-cells still have good hardness and toughness and are not easily broken when subjected to various mechanical forces such as shear, impact, extrusion, etc., while ordinary cells are quickly crushed into particles of tiny particles.

At the same time, a small amount of soluble sugar, crude protein, cellulose, and mineral elements present in the heterocysts are also gradually dissolved in the liquid medium and are removed through solid-liquid separation, so that the wet production of fine powder is purer than the dry production.

The solvent is divided into two categories: organic solvents and salt reagents. Organic solvents only ethanol, isopropanol suitable for fine powder processing of solvent blocking, of which ethanol price is the lowest, the most commonly used, ethanol as a solvent blocking, at 20 ℃ under the effective concentration of 30% (v/v).

Salt reagents only sodium tetraborate (borax) suitable for konjac powder wet processing of solvent blocking, but because boron is toxic, and banned in food processing, can only be used for non-food konjac fine flour processing.

3. Konjac flour processing methods

3.1 Ordinary Konjac flour dry processing

Take the processing of hammer blade equipment as an example:

(1) Process flow: Konjac chips → processing in the fine powder machine → wind separation → grinding in the mill → wind separation → sieving → grading → mixing and homogenization → packaging and storage.

(2) The main equipment at present in China is a type of fine powder processing machine (MJO) is the main, its models are 300, 400, 450, and 500, to improve the quality of fine powder after 1995 a scraper-type turbo konjac fine powder grinder.

So far, the formation of the konjac powder dry processing equipment system, by the crusher, MI-450 type konjac flour processing machine, 400 type konjac fine powder research machine, separation tank, cyclone dust collector, bag dust collector and three-dimensional vibrating screen and other components.

(3) Operational steps

① Raw materials to prepare Konjac chips (corner) of the quality directly affects the quality of fine powder, should be selected color white, moisture content of about 13% ~ 15% of the Konjac chips, where the “black heart” and baking scorched can not prepare special pole, a fine powder.

Selected Konjac chips are poured on the screen plate so that small particles and debris leak down, pay special attention to the removal of hair and other miscellaneous matters that can not enter the food, but also in the bottom of the screen plate to fix a few magnets to remove the metal slag, to prevent entry into the fine powder machine.

② Start the fine powder machine, close the gate on the switchboard, energize the control cabinet, and then start the parts of the machine in the order specified in the manual.

③ When the feeding indicator light on the feeding machine is on, put the konjac chips, which are weighted according to the specified amount of each feeding, into the hopper evenly, and the feeding time is about 20 seconds.

④ Crushing and grinding and discharging After feeding, crushing, grinding, and separating reach a predetermined time, the fine powder will be discharged automatically.

⑤ Grinding in the grinder The fine powder is fed into the grinder for further grinding, and the flying powder impurities are sucked away through the suction (this step can be omitted if only general quality is required).

⑥ Sieving, testing, homogenizing, and packaging The unloaded fine powder is poured into the sifter for sieving, and the mesh has several apertures such as 40 mesh, 60 mesh, 80 mesh, 100 mesh, 120 mesh, 140 mesh, etc.

The sifter can be used to sift the fine powder into the sieve. Sieve mesh aperture size, and particle size level according to requirements.

After the points for quality testing, including viscosity, sulfur dioxide, moisture, and particle size. Then the same type of fine powder is fully mixed with a mixer to ensure the uniformity of output, and finally packaged.

3.2 Konjac ordinary flour wet processing

Glucan particles contain more than 10% impurities, which are difficult to remove by the dry method, and the wet method can remove soluble impurities on the surface and inside of the cells. The wet method makes glucomannan particles in the liquid medium expand, and break through the ordinary cells of the package.

So that the glucomannan particles and ordinary cells of the connection are loose, and easy to separate without long time crushing and grinding, can reduce the loss of glucomannan.

Thus the fine powder yield of the dry method is about 3 percentage points higher than the wet method of about two types of wet konjac flour processing, namely, organic wet and inorganic wet, the development of the direction of the organic wet method.

(1) Organic wet method

① Process: Fresh Konjac bulb cleaning, peeling → (cut) → color protection → crushing → desolventization and decontamination → grinding → desolventization and decontamination → washing → drying → dry milling → sieving → homogenization → inspection → packaging.

② Main Equipment Washing and Cutting Equipment; Powder Research Equipment; Separation Equipment; Vacuum Drying Equipment; Generator and Condenser.

③ Wet processing technology

1. Fresh Konjac cleaning and peeling.

2. Cut and color protection if you use the wheel crushing research, must first use the cutter to peel the fresh konjac cut into small pieces, if you use the shear drum-type crusher does not have to cut the pieces.

Color protection with an effective SO2 concentration of 25mg/L ~ 100mg/L children’s sulfite solution, generally used in the first crushing medium to join.

FAQ

Can konjac be eaten raw?

Konjac can not be eaten raw.

Although konjac is rich in nutritional value, but raw konjac is toxic, and can not be eaten raw, if eaten directly will lead to food poisoning, generally needs to be processed to reduce the toxicity of the treatment, can be eaten.

What will happen if konjac is eaten raw?

Konjac will be poisoned if eaten raw. Konjac poisoning mainly paralyzes the respiratory center and motor center, so a series of symptoms of poisoning, initially visible throat and stomach and intestines have a spicy or burning sensation, followed by salivation, nausea, vomiting, abdominal pain, sweating, speech not clear, panic palpitations, pallor, respiratory irregularities, or even respiratory center is completely paralyzed to death.

What to do if you eat konjac raw?

1, Edible vinegar with ginger juice.

Konjac cold flavor Xin, poisonous, is an alkaline food, if accidentally konjac poisoning, folk commonly use vinegar with a little ginger juice, internal or containing gargle, can be poisoned toxicity, can be detoxified.

2, Timely medical.

If the konjac poisoning is more serious, nausea and dry vomiting, abdominal pain, speech is not clear, panic palpitations, paleness, and breathlessness, must be timely to the hospital to receive treatment, so as not to cause irreparable damage.

How to eat konjac?

1, Buy processed konjac.

Konjac is toxic when eaten raw, so it is best to buy processed Konjac products, such as konjac tofu, konjac noodles, these have been detoxified, and it is recommended that the best thing to do is to cook with water before eating, or on the pot to stir-fry before eating.

2, Raw konjac needs to be decocted to remove the poison.

If you buy raw konjac, must not be eaten directly, and needs to be decocted more than 3 hours to eat.

One thought on “Konjac Bulb Konjac Flour Processing”

WONDERFUL Post.thanks for share..extra wait .. …